A piston is a cylindrical engine component that slides back and forth in the cylinder bore by forces produced during the combustion process. The piston acts as a movable end of the combustion chamber. The stationary end of the combustion chamber is the cylinder head. Pistons are commonly made of a cast aluminum alloy for excellent and lightweight thermal conductivity. Thermal conductivity is the ability of a material to conduct and transfer heat.

Aluminum expands when heated, and proper clearance must be provided to maintain free piston movement in the cylinder bore. Insufficient clearance can cause the piston to seize in the cylinder. Excessive clearance can cause a loss of compression and an increase in piston noise.

There are also secondary functions fulfilled by the piston:

contributes to heat dissipation generated during combustion

ensures the sealing of the combustion chamber, preventing gas leakages from it and oil penetration into the combustion chamber

guides the movement of the connecting rod

ensures to the continuous change of gases in the combustion chamber

generates the variable volume in the combustion chamber

The piston is the component of the internal combustion engine (ICE) which has to sustain the most mechanical and thermal stress. Due to the piston, the power of the ICE is limited. In case of very high thermal or mechanical stress, the piston is the first component to fail (compared to engine block, valves, cylinder head). This is because the piston must be a compromise between mass and mechanical and thermal stress resistance.

The geometry of the piston is constrained due to the cubic capacity of the ICE. Therefore, the main way to increase the mechanical and thermal resistance of the piston is by increasing its mass. This is not recommended because a piston with high mass, has high inertia which translates in high dynamic forces, especially during high engine speed. The resistance of the piston can be improved by geometry optimization but there will be always a compromise between mass and mechanical and thermal resistance.

As you can see there are significant differences between diesel and gasoline pistons. Diesel pistons must withstand higher pressures and temperatures, therefore they are bigger, bulkier and heavier. They can be manufactured from aluminium alloys, steel or a combination of both. Gasoline engine pistons are lighter, designed for higher engine speeds. They are manufactured from aluminium alloys.

The piston crown comes in direct contact with the burning gases, within the combustion chamber, so it’s exposed to high thermal and mechanical stress. Depending on the type of the engine (diesel or gasoline) and the type of fuel injection (direct or indirect injection), the piston crown can be flat or can contain a bowl.

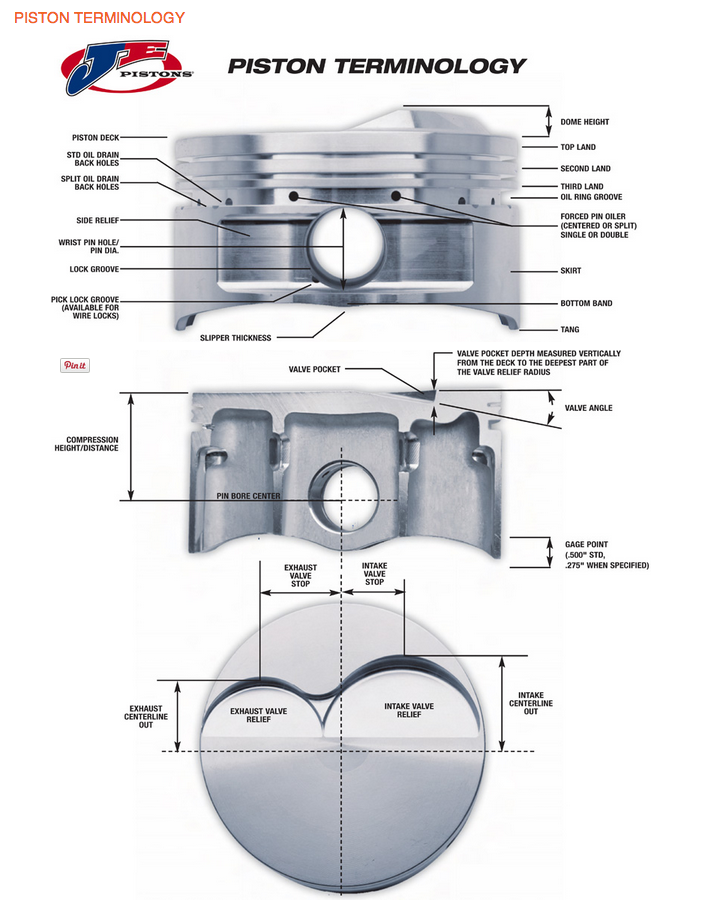

PISTON PARTS

1. piston pin

2. skirt

3. ring grooves

4. ring lands, and

5. piston rings.

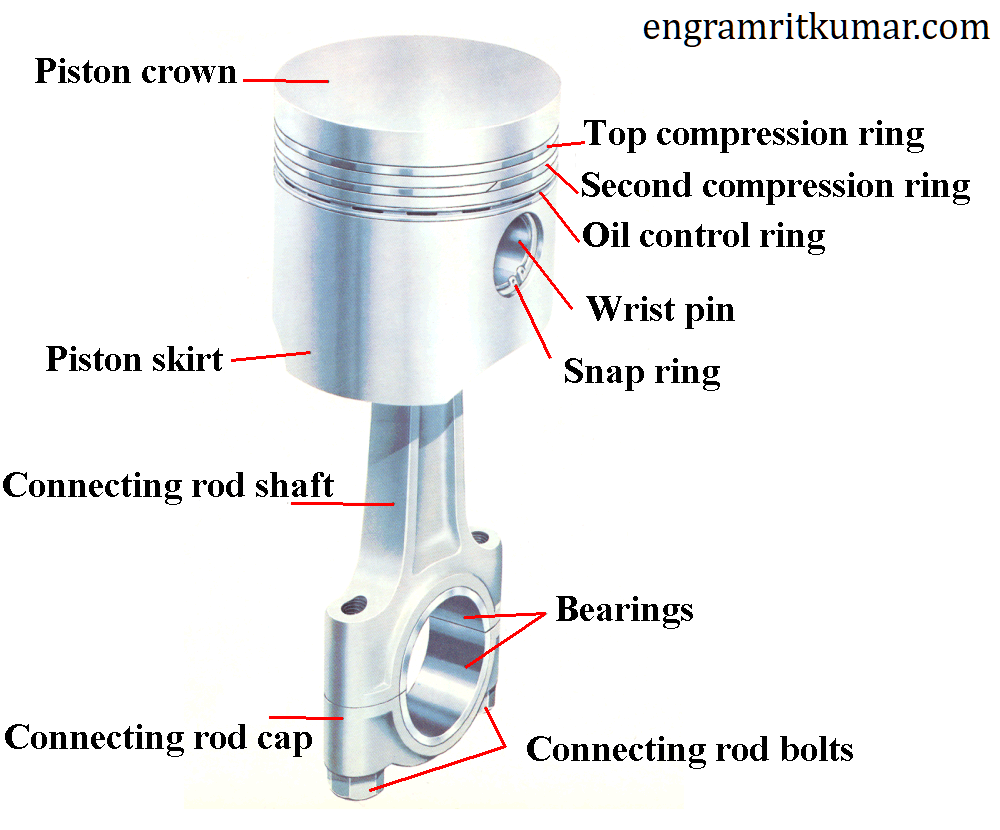

1. Piston head

It is the top surface (closest to the cylinder head) of the piston which is subjected to tremendous forces and heat during normal engine operation.

2. Piston pin bore

A piston pin bore is a through hole in the side of the piston perpendicular to piston travel that receives the piston pin.

3. Piston pin

A piston pin is a hollow shaft that connects the small end of the connecting rod to the piston.

4. Skirt

The skirt of a piston is the portion of the piston closest to the crankshaft that helps align the piston as it moves in the cylinder bore. Some skirts have profiles cut into them to reduce piston mass and to provide clearance for the rotating crankshaft counterweights.

5. Ring grooves

A ring groove is a recessed area located around the perimeter of the piston that is used to retain a piston ring.

6. Ring land

Ring lands are the two parallel surfaces of the ring groove which function as the sealing surface for the piston ring.

7. Poston ring

A piston ring is an expandable split ring used to provide a seal between the piston an the cylinder wall. Piston rings are commonly made from cast iron. Cast iron retains the integrity of its original shape under heat, load, and other dynamic forces. Piston rings seal the combustion chamber, conduct heat from the piston to the cylinder wall, and return oil to the crankcase. Piston ring size and configuration vary depending on engine design and cylinder material.

Piston rings commonly used on small engines include:

1. Compression Ring

2. Wiper Ring

3. Oil Ring

1. Compression ring,

A compression ring is the piston ring located in the ring groove closest to the piston head. The compression ring seals the combustion chamber from any leakage during the combustion process. When the air-fuel mixture is ignited, pressure from combustion gases is applied to the piston head, forcing the piston toward the crankshaft. The pressurized gases travel through the gap between the cylinder wall and the piston and into the piston ring groove. Combustion gas pressure forces the piston ring against the cylinder wall to form a seal. Pressure applied to the piston ring is approximately proportional to the combustion gas pressure.

2. Wiper ring

A wiper ring is the piston ring with a tapered face located in the ring groove between the compression ring and the oil ring. The wiper ring is used to further seal the combustion chamber and to wipe the cylinder wall clean of excess oil. Combustion gases that pass by the compression ring are stopped by the wiper ring.

3. Oil ring

An oil ring is the piston ring located in the ring groove closest to the crankcase. The oil ring is used to wipe excess oil from the cylinder wall during piston movement. Excess oil is returned through ring openings to the oil reservoir in the engine block. Two-stroke cycle engines do not require oil rings because lubrication is supplied by mixing oil in the gasoline, and an oil reservoir is not required.

TYPES OF PISTONS

There are three types of pistons, each named for its shape: flat top, dome, and bowl.

1. Dome Piston

The Dome Piston looks just like it sounds. Instead of a flat top it has a dome that looks like the top of a dome stadium. Piston Dome refers to the amount of added volume on top of the piston compared to a flat top piston. This added volume increases the Compression Ratio and therefore should increase performance. However, depending on the shape of the combustion chamber in the head, highly domed pistons can create slow burning, inefficient combustion chambers. The optimum tradeoff between higher compression ratio and dome/combustion chamber shape can only be determined by trial-and-error on a dyno.

Dome Pistons are also used in 2 stroke engines, mostly to deflect the inlet charge up toward the spark plug, and not let it flow directly to the exhaust ports.

2. Bowl Piston

Bowl pistons typically are used to reduce compression ratio because of the added volume of the bowl to the combustion volume. Because they reduce Compression Ratio, bowl pistons can be used in Turbo Charged or Super Charged engines to help avoid detonation (spark knock) under boosted conditions. The extreme bowl shown is used in diesel engines, where the bowl is used to confine the diesel fuel spray for good, fast combustion. A piston bowl can do the same for a spark ignition engine and make for a fast burning, compact combustion chamber.

3. Flat Top Piston

The Flat Top Piston is just like it sounds; it has a flat top. These pistons are typically used in mass produced engines. They are easy to manufacture and this keeps the cost of the engines low.

4. Flat Top Piston with Valve Relief

The Flat Top with Valve Relief is basically a Flat Top Piston but they have small amounts of material removed to keep the valves from hitting the piston when the intake and exhaust valves are opening or closing. This allows for higher compression ratios by allowing the piston to go higher into the cylinder head.