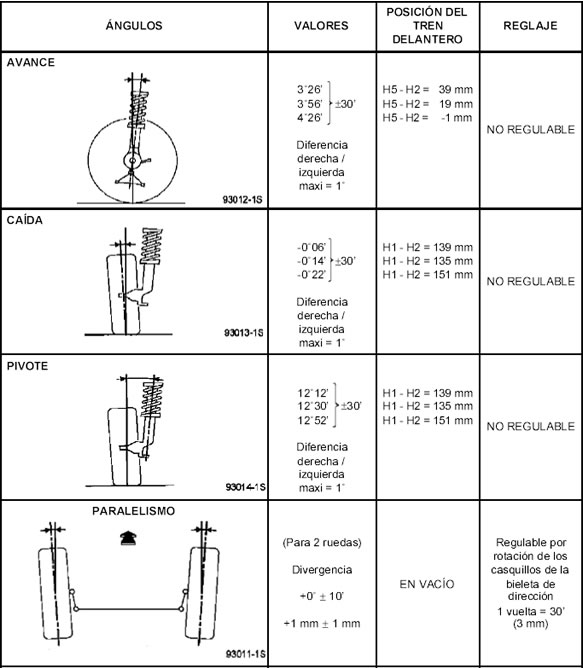

Cómo funciona?

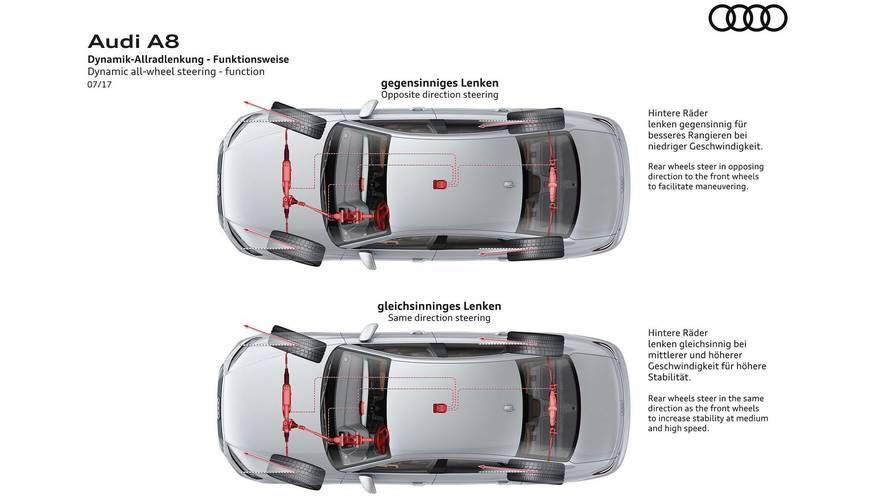

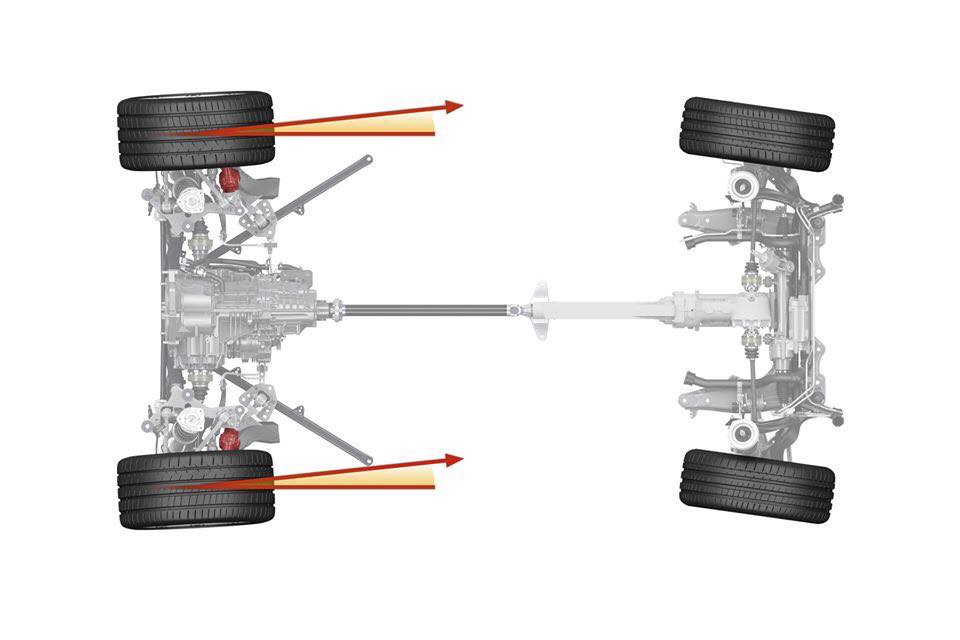

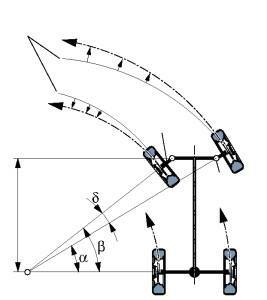

El principio de Ackerman enuncia que cuando un vehículo gira en una curva, los ejes de todas las ruedas deben concurrir en un punto, el centro instantáneo de rotación. La mangueta de la rueda interior debe de girar un ángulo mayor que la de la rueda exterior, luego se precisa una divergencia de las ruedas delanteras cuando se toman las curvas para evitar el desgaste de las cubiertas y evitar el deslizamiento. Con el mecanismo, anteriormente mencionado, conseguimos una geometría óptima para la dirección. Para seguir este principio se hace que el ángulo de giro de la rueda interior sea mayor que la exterior, es decir, como se muestra en la figura.

Cuando un vehículo describe una curva, todas las ruedas deben girar entorno al mismo centro instantáneo de rotación, permitiendo un mejor control y minimizando el desgaste de las ruedas. Cada una de las ruedas directrices debe por ello describir un arco de diferente radio, siendo el radio del arco que describe la rueda exterior mayor que el de la interior.

Se denomina centro instantáneo de rotación al punto respecto al cual un sólido está girando en un instante. La línea que une el centro instantáneo de rotación y un punto cualquiera del sólido es perpendicular a la velocidad de dicho punto.

Según Ackermann, el ángulo que forma la rueda exterior con la extensión del eje trasero (α) ha de ser menor que el formado por la interior (β).

Si un vehículo se diseña sin tener en cuenta el principio de Ackermann y las dos ruedas delanteras giran el mismo ángulo, no estarán girando con respecto al mismo punto. Esto genera inestabilidad y desgaste excesivo del neumático.

En caso de aplicarse el principio de Ackermann, la rueda interior girará con mayor ángulo de forma que el centro instantáneo de rotación sea el mismo para todas las ruedas.

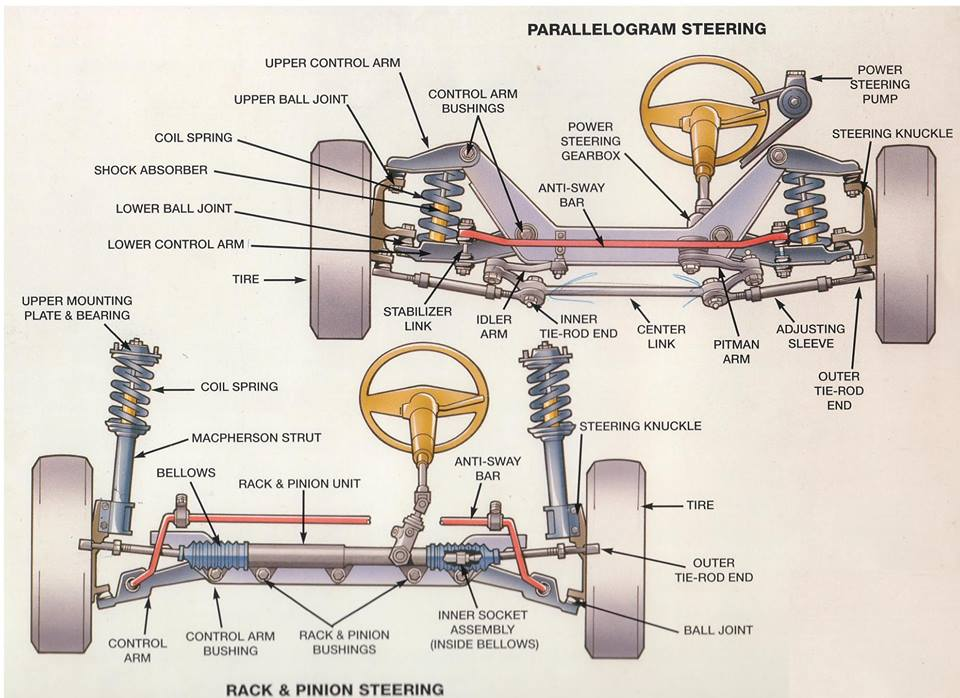

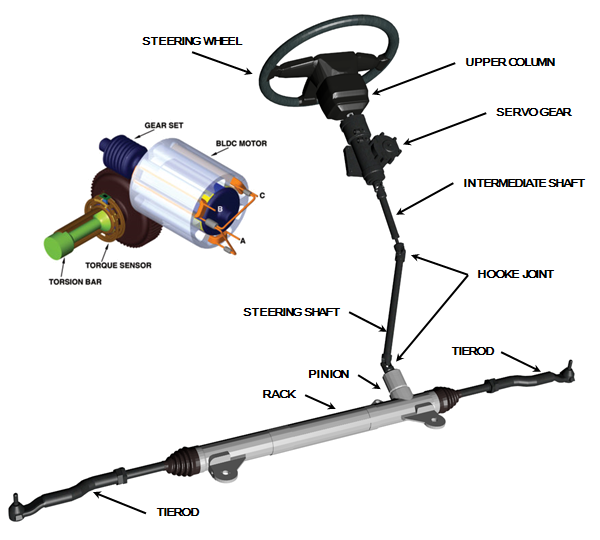

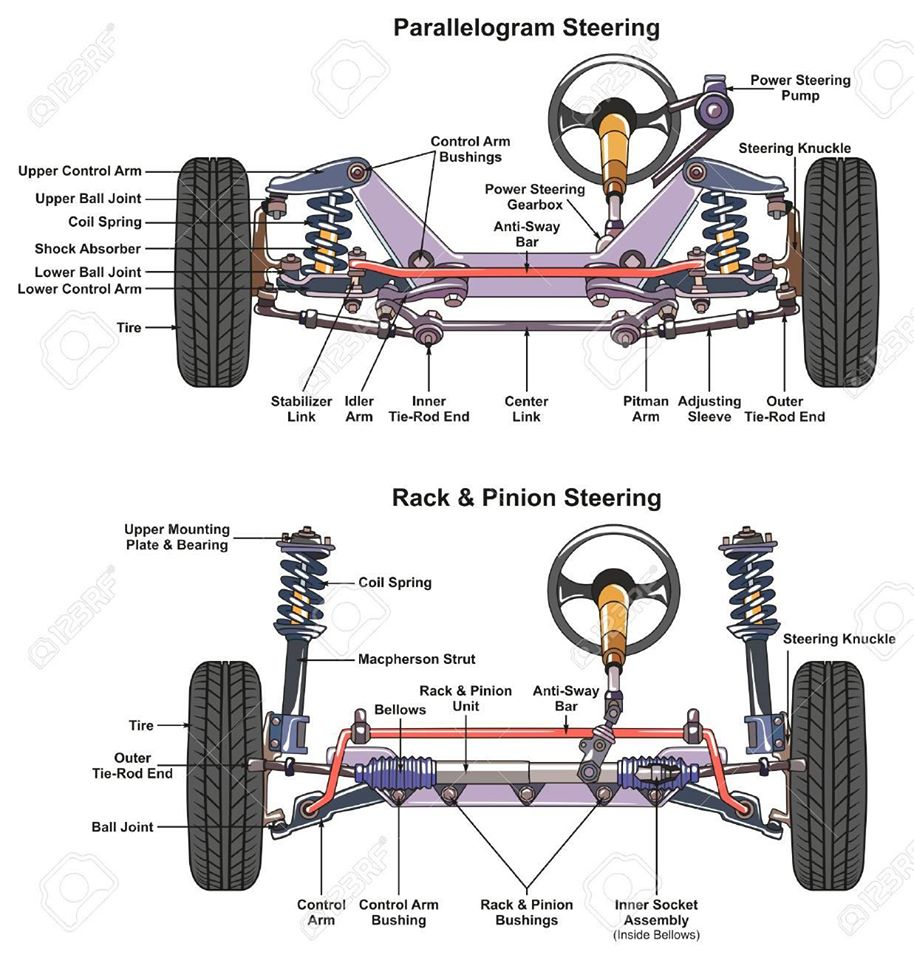

Para conseguir este efecto, las bieletas de dirección formarán cierto ángulo con el eje longitudinal, como se describe en la imagen inferior.

El cálculo de Ackermann se basa en la fórmula:

Via/Batalla = cotg(α) – cotg(β)

La formula para calcular Ackermann se obtiene despejando α de la anterior, de modo que:

Ackermann = arctan ( batalla / (batalla/tan(β) – via) )

Porcentaje = 100 · ( α / Ackermann )

Un 100% Ackerman significa que las prolongaciones de las bieletas se cortan en el centro del eje trasero. En caso de que el porcentaje sea superior a 100, éstas se cortarán por delante del eje trasero; y detrás si es inferior.

Todo esto está muy bien en teoría, pero en la práctica los neumáticos se deforman. A esta deformación se la conoce como ángulo de deriva y es la diferencia entre el ángulo de giro y el ángulo que realmente adquiere la superficie de contacto del neumático debido a las fuerzas que se ejercen sobre él.

En los vehículos modernos no se utiliza un sistema de dirección Ackermann puro. Debido a la transferencia lateral de masas, las ruedas en las que la carga es menor, requieren menos ángulo de deriva para llegar a su límite de adherencia.

Para conseguir los efectos deseados en la geometría se debe introducir el concepto de convergencia.

Si la convergencia es positiva, las dos ruedas directrices tendrán cierta convergencia hacia el centro de las trayectorias, es decir, la rueda interior tratará de describir una circunferencia ligeramente mayor y la exterior una circunferencia ligeramente menor a la que está siguiendo. Con esta geometría se reduce el ángulo de deriva de la rueda interior y se aumenta el de la exterior.

En caso de que la convergencia sea negativa la rueda interior tratará de describir una circunferencia menor a la que está siguiendo y la exterior una circunferencia mayor. Con esta geometría el ángulo de deriva de la rueda interior aumenta, reduciéndose el de la rueda exterior.