EXHAUST SMOKE: TYPES (BLACK, WHITE, AND BLUE) AND CAUSES

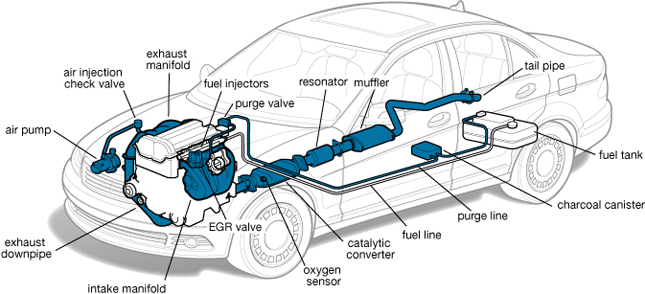

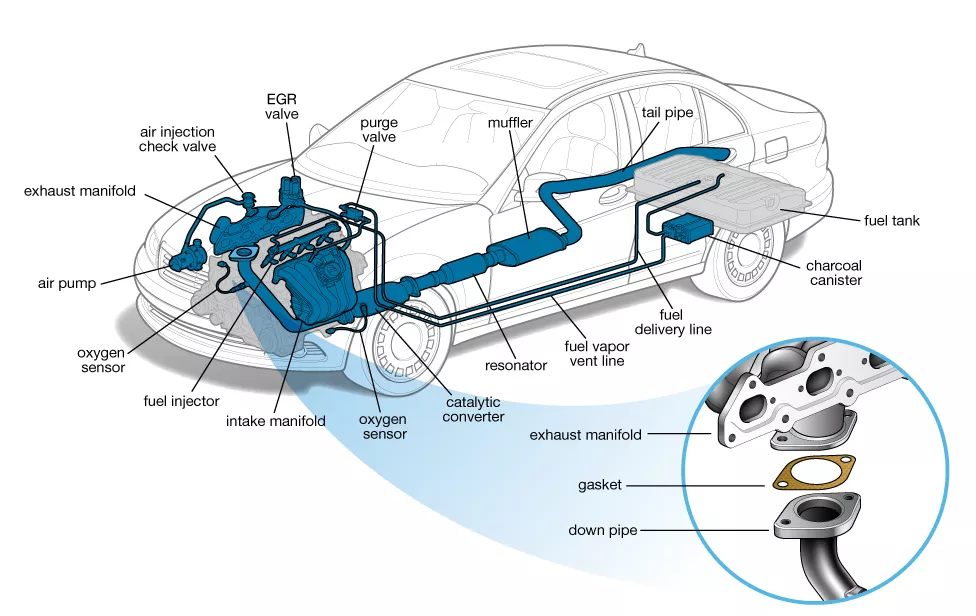

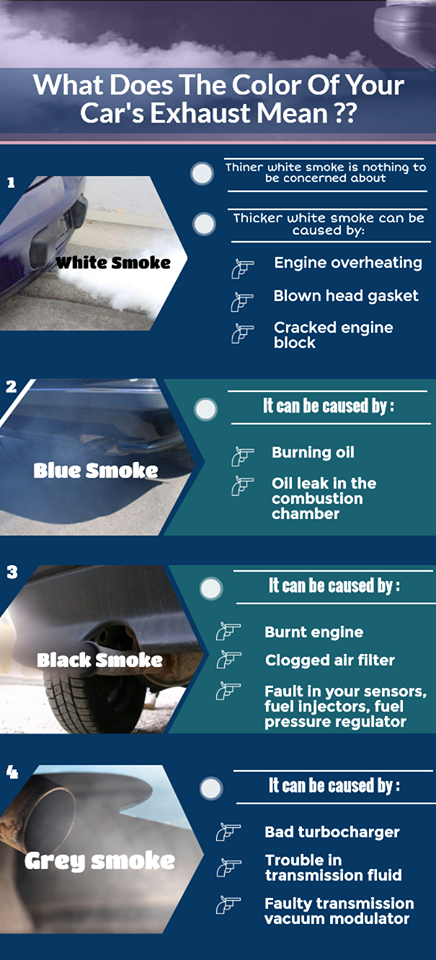

Exhaust smoke is a way of your car communicating with you to say what is wrong. Usually, the smoke that gets emitted is black, white, grey and blue. The exhaust gases are an old school way to detect symptoms of problems i.e. large amounts of black smoke may mean the EGR is blocked and it’s over-fueling.

Knowing the difference between the smokes that comes from the exhaust is very useful. If you are not going to fix the car yourself, take note when the smoke appears and the color and report back to your mechanic. Avoiding the problem will only shorten the life of the engine and result in unnecessary repair bills.

TYPES OF EXHAUST SMOKES

1. White smoke

2. Black smoke

3. Blue smoke

1. WHITE SMOKE

Thick white smoke can be caused by the engine burning coolant. This can be caused by the coolant leaking into the engine due to a leak in the head gasket, a damaged cylinder head or a cracked engine block. If you happen to see this kind of smoke take your car to the garage as soon as possible as the leaking coolant can lead to overheating which could cause damage to your engine. Not to mention chances of coolant mixing with the oil.

White smoke has a varying amount of causes and symptoms, which are more common in gasoline cars. The most common cause of white smoke is when the car has just been started. The white smoke is just steam from condensation that clears as the car warms up.

White Smoke from Petrol/Gasoline Car

White smoke as mentioned is usual from startup however if it continues when warm, you have a problem. Check the following for white smoke causes in petrol cars:

1. Head Gasket Failure.

A common issue with cars that have been neglected or simply the gasket has reached the end of its lifespan. Try using a head gasket sealer and testing to see if any smoke appears and you would have located the issue.

2. Turbo Issues

The turbo usually emits white or grey smoke that mostly appears under acceleration. Not as common but seals and pumps do fail and turbos problems get worse with old age.

3. Overheating Engine.

In some cases, certain engines tend to bellow out white smoke when they are too hot. Check the temperature next time there is white smoke. If it is overheating, look into potential causes, such as broken fans or no water.

4. Cracked Engine Block.

Not that common but a cracked engine block will force white smoke to the exhaust. This sort of damage to the block can cause a car to become written off by the insurance companies.

White Smoke from Diesel Car

Sadly, white smoke from a diesel car operating at its optimum temperature is bad news in most cases. Check for the following for white smoke in diesel cars:

1. Worn or Leaking Injectors.

The seals on the fuel injectors are prone to breaking down and eventually leak. This can cause a blueish/white smoke to bellow from the exhaust. Take a look on your engine bay to see if there are any signs of leakage, usually in the form of black carbon build-up.

2. Poor Quality Diesel.

Often poor quality fuel can cause a blueish mix of white smoke to emit from the exhaust. It’s always best to use high-quality injector cleaner to treat your diesel fuel.

3. Low Cylinder Compression.

Usually caused by other components such as piston rings becoming worn out

2. BLACK SMOKE

Black smoke that gets emitted from a car is more common in diesel cars. Apart from when the car is cold, white smoke should never appear from a diesel car exhaust. The majority of older diesel cars will bellow black smoke under heavy acceleration but new diesel engines will not emit any black smoke.

Black Smoke from Petrol/Gasoline Car

Black smoke in petrol/gasoline cars will is often the result of a rich mixture from the distributor. This will result in very poor miles per gallon and extra stress on engine components.

1. Rich Mixture.

A rich fuel mixture or air mixture will cause black smoke under acceleration or revving. This can be a result of a distributor unit providing too much fuel to the injectors or not enough air getting to the fuel. Some cars are tuned to run rich such as the Mitsubishi Evo.

2. Not Enough Air.

A clogged air filter or not enough air getting to the intake system completely offset the air to fuel ratio.

Petrol engines very rarely emit black smoke from the exhaust compared with diesel cars. In almost all circumstances, black smoke from a petrol car is due to the air to fuel ratio.

Black smoke from a diesel car

Black smoke from a diesel car is the result of poor combustion of the fuel. In my experience, the issue is either due to insufficient airflow or poor quality diesel that builds up into a carbon deposit. Causes of black smokes from diesel car exhausts are the following:

1. Clogged Air Filters

With dust blocking the air filter, there are chances that sufficient air amount is not reaching the cylinder. As a result, more fuel is being burnt. And, ultimately this causes black smoke from exhaust irrespective of the fact that the fuel injectors are working properly.

Besides this, due to the heavy load or during hard acceleration also black smoke can be found, as the fuel is not injected at the right time.

2. Damaged Fuel Injectors

In case of the good fuel injector, the fuel is properly atomized, which means the fine droplets of fuel are spreading equally in the cylinder. However, if the injectors don’t close on time or they are clogged, there are chances that more fuel is injected in a certain area called a rich mixture area of the car. In this situation, even the amount of air is insufficient for the combustion of fuel due to blocked injectors (and the few opened ones inject only fuel).

As a result, solid carbon is formed from the fuel not burnt, which is emitted as black smoke from the tailpipe of the car.

3. Faulty MAF Sensors

The work of the Mass Airflow sensor is to determine the volume of air entering the engine, which in turn, helps in measuring the amount of fuel to be injected inside the cylinder. This entire functioning is important for the complete combustion of fuel in the engine. Otherwise, a malfunctioning MAF sensor can lead to poor performing engine.

4. Bad EGR Valve

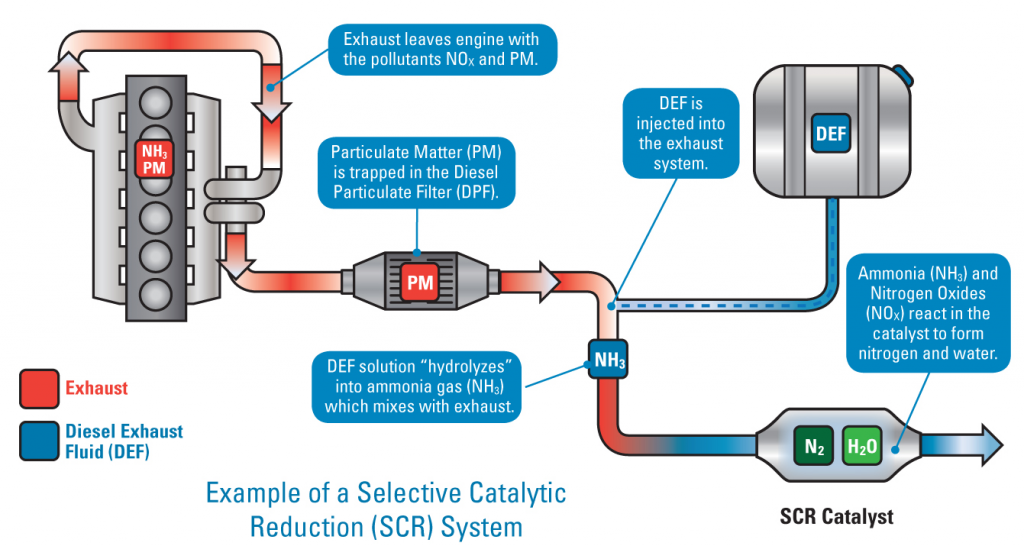

The EGR reduces the emission of nitrogen oxides by a re-circulating portion of an engine’s exhaust gas to the internal combustion engine. If this component is damaged, it emits all the black smoke out of the exhaust.

5. Damaged Piston Rings

One possible reason behind black smoke from the exhaust pipe is damaged piston rings. Piston Rings are designed to prevent the infiltration of engine oil inside the combustion chamber. If there is any problem with the piston rings, the engine oil starts flowing into the combustion chamber. The combustion of the mixture of this engine oil and the fuel delivers black smoke.

6. Engine Deposits

Engine deposits are another reason causing black smoke from the tailpipe. When the engine is new, it will run fluently without any problems. But after a long period of use, the engine conditions get worse and worse and this consists of getting accumulations of combustion product in important areas like combustion chambers and injectors. And these interfere with the best functioning.

7. Poor Quality Diesel Fuel.

Poor quality fuel will also cause black smoke (as well as white) to come from the exhaust. Using a diesel additive to clean vital components can fix this problem, which we recommend to do on a full tank basis.

8. Faulty Turbocharger and Bad Air to Fuel Ratio.

Diesel fuel requires an adequate air ratio in order to perform as it should from the factory. The poor ratio is usually caused through a faulty turbo, dirty/old air filter and sensors that control airflow. With bad air to fuel ratio, performance will be reduced significantly.

9. Over Fueling or ECU Chip/Tuning/Remap.

The term basically means that too much diesel is being pumped from the fuel pump. This has the potential to crack a cylinder head if it’s over fueling excessively. However, if the diesel car has been tuned or remapped, over-fueling (and over boosting) is common. I had a 1.9 TDi that was remapped, which would leave a black smokescreen in my rear mirror under heavy acceleration.

3. BLUE SMOKE

Blue smoke is an indication that the car is burning engine oil. This happens when the piston rings are worn out and oil is leaking to the combustion chamber where it is burned together with the fuel. For a turbocharged car, the smoke is a sign that the blower is in need of replacement. Burning oil can cause rough starts due to the fact that it can ruin a car’s spark plugs.

1. Stuck PVC Valve

If you observe blue smoke appearing in your car all the time, PCV (Positive Crankcase Ventilation) Valve will be the first thing you should check. The function of the PCV valve is releasing the pressure (which builds up in the Oil Pan) into the Intake Manifold (where the engine gets its air for running). The Intake Manifold is linked to the Air Filter of your engine too. So if the PCV Valve gets stuck, it will keep mixing the oil with air and other gases inside the engine. The combustion of this mixture will cause blue smoke.

2. Worn Engine

The worn engine is another culprit responsible for blue smoke from the exhaust.

Each engine has pistons which are moved up and down a cylinder. Each piston has metal rings around its side like bracelets. The function of these rings is to help the piston forming a tight seal against the cylinder. So if the rings or cylinder is worn out, oil from below the piston will come up. Then the oil gets mixed with the Air and Gasoline and gets burnt, causing the blue smoke.

3. Blown Turbo

Blown turbo is a probable reason causing blue smoke in cars that have Turbos. Blue smoke will suddenly appear in a big cloud if your car blows a Turbo. A blown turbo is either the turbo casing has damaged or a broken oil seal in the Turbo. In both cases, they let oil into the intake of the engine.

4. Blue Smoke Comes With Transmission Fluid Loss

A modulator is used to control the transmission shift in older vehicles with vacuum controlled automatic transmissions. If there is any problem with the modulator like a failed diaphragm, it enables the engine to suck in transmission fluid. Then this transmission fluid will be burnt like oil, creating the blue smoke coming out of the exhaust.