EXHAUST SYSTEM: COMPONENTS AND THEIR FUNCTION

The exhaust system collects the exhaust gases from the cylinders, removes harmful substances, reduces the level of noise and discharges the purified exhaust gases at a suitable point of the vehicle away from its occupants…

FUNCTION

The exhaust system collects the exhaust gases from the cylinders, removes harmful substances, reduces the level of noise and discharges the purified exhaust gases at a suitable point of the vehicle away from its occupants. The exhaust system can consist of one or two channels depending on the engine. The flow resistance must be selected so that the exhaust back pressure affects engine performance as little as possible. To ensure that the exhaust system functions perfectly, it must be viewed as a whole and developed accordingly. This means that its components must be coordinated by the design engineers in line with the specific vehicle and engine.

In addition to all the complex functions which the exhaust system has to perform, it is also subject to extreme stresses. The fuel-air mixture in the cylinders is abruptly heated to temperatures up to 2,400 °C. This causes it to expand greatly before escaping into the exhaust system at supersonic speed. This noise level resembles the crack of an explosion and must be reduced by approx. 50 dB(A) as it travels from the engine exhaust valve to the end of the exhaust system.

Apart from temperature and pressure stresses, the exhaust system must also cope with vibrations from the engine and bodywork as well as vibrations and jolting from the carriageway. The exhaust system additionally has to resist corrosion attacking from the inside caused by hot gases and acid, and from the outside in the form of moisture, splashed water and salt water. There is also the risk that the catalyst may be poisoned through sulfur or lead present in the fuel.

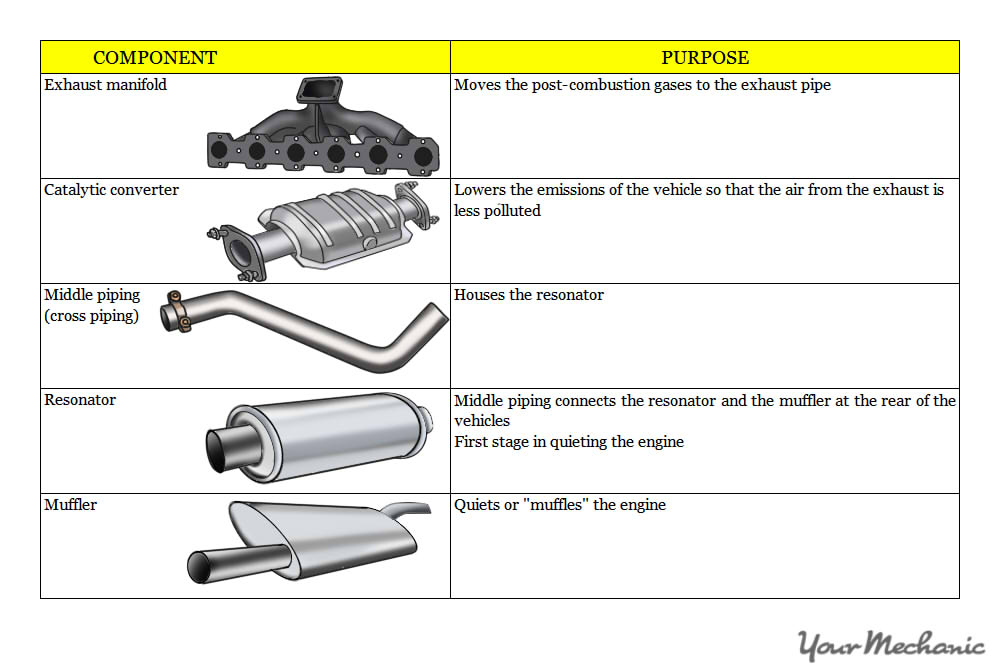

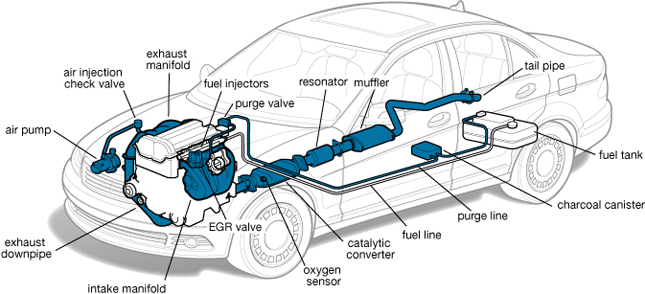

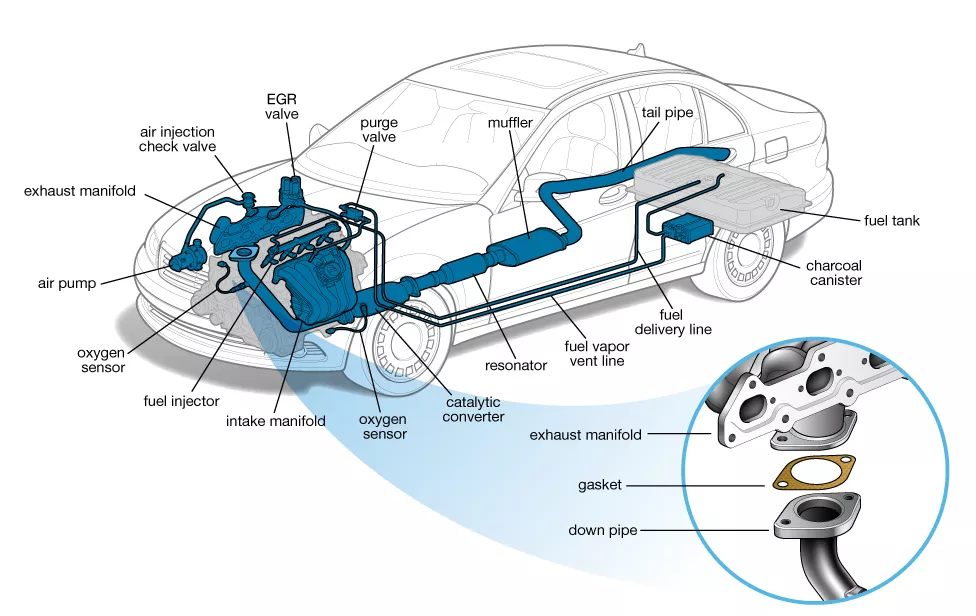

COMPONENTS OF EXHAUST SYSTEM

1. Exhaust manifold:

The exhaust manifold attaches to the cylinder head and takes each cylinder’s exhaust and combines it into one pipe. The manifold can be made of steel, aluminum, stainless steel, or more commonly cast iron.

2. Oxygen sensor:

All modern fuel injected cars utilize an oxygen sensor to measure how much oxygen is present in the exhaust. From this, the computer can add or subtract fuel to obtain the correct mixture for maximum fuel economy. The oxygen sensor is mounted in the exhaust manifold or close to it in the exhaust pipe.

3. Catalytic converter:

This muffler like part converts harmful carbon monoxide and hydrocarbons to water vapor and carbon dioxide. Some converters also reduce harmful nitrogen oxides. The converter is mounted between the exhaust manifold and the muffler.

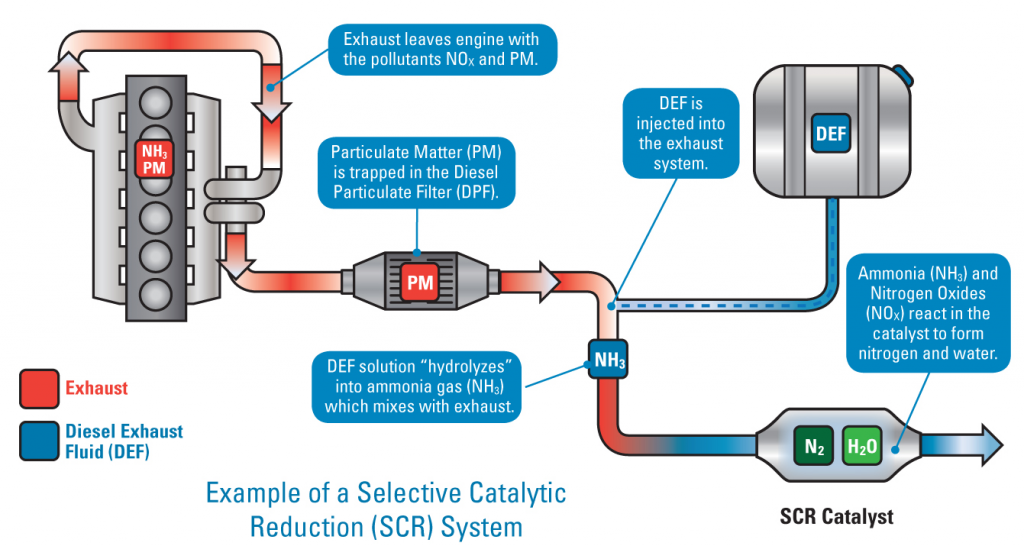

Selective Catalytic Reduction (SCR)

This technology uses ammonia to break down dangerous NOx emissions produced by diesel engines into nitrogen and water. In automotive applications, SCR delivers ammonia through a urea solution – Diesel Exhaust Fluid (DEF) – which is sprayed into the exhaust stream by an advanced injection system and then converted into ammonia on a special catalyst.

SCR is the technology of choice for the majority of truck and engine manufacturers to meet 2010 emissions standards for heavy-duty trucks.

Aside from helping the environment, the biggest benefit of SCR for vehicle owners is the fuel efficiency the technology provides. Because SCR deals with emissions in the exhaust pipe, engineers are able to tune the engine to provide more torque and reduce fuel consumption.

4. Muffler/Silencer:

Every internal combustion engine produces «exhaust noise» due to the pulsating emission of gases from the cylinders. This noise has to be silenced by reducing the sound energy of the exhaust gas flow. There are two basic options here: Absorption and reflection of the sound in the silencer. These two principles are generally combined in a single silencer. Exhaust chambers and exhaust flaps are other sound-absorbing and sound-modifying elements that can be used to eliminate especially undesirable frequencies from the outlet noise. Catalytic converters also have a sound-absorbing effect.

The exhaust system is itself a system subject to vibration, it produces noise itself through natural frequencies and vibration which are transmitted to the car body. Careful coordination of the entire system is, therefore, necessary here. This includes the design and positioning of the individual elements of the exhaust system and their flexible mountings.

The muffler serves to quiet the exhaust down to acceptable levels. Remember that the combustion process is a series of explosions that create a lot of noise. Most mufflers use baffles to bounce the exhaust around dissipating the energy and quieting the noise. Some mufflers also use fiberglass packing which absorbs the sound energy as the gases flow through.

5. Resonator

The muffler alone cannot always quiet all the engine noise. Many exhaust systems also include a resonator which is like a mini-muffler. They are usually straight pipes filled with sound muffling materials. The resonator can be either before or after the muffler in the exhaust system.

6. Exhaust pipe:

Between all of the above mention parts is the exhaust pipe which carries the gas through it’s journeys out your tailpipe. Exhaust tubing is usually made of steel but can be stainless steel (which lasts longer due to its corrosion resistance) or aluminized steel tubing. Aluminized steel has better corrosion resistance than plain steel but not better than stainless steel. It is, however, cheaper than stainless steel.

HOW TO IDENTIFY PROBLEMS

Although the exhaust system is located underneath the vehicle, there are some symptoms you can look out for which may indicate that there is a problem with your exhaust.

1.Noises

A loud roaring noise could indicate corrosion to the exhaust system

A hissing sound could mean that gas is escaping through a crack or hole in one of the exhaust components

Chugging noises mean that there may be a blockage in one of the pipes

A persistent and rapid succession of knocking sounds indicate that a part of the exhaust may have come loose

2. Emissions

White smoke – this is not smoke but in fact, vapor and you should see this when you first start your car as it indicates that the engine is warming up. If white smoke is visible after the engine is warm it may indicate internal leaks or cracks.

Blue smoke – A bluish-grey smoke means that oil may be burning in the combustion chamber. This could mean that the cylinder is worn or there are leaks in the valve seals.

Black smoke – very black smoke is often accompanied by increased fuel consumption and may signify leaks in the exhaust system or a problem with the engine.

3. Visual

Inspect the components of your exhaust that you can see for any signs of rust or corrosion. Make sure you keep an eye out for any cracks and holes and contact a specialist if you do find any signs of damage.