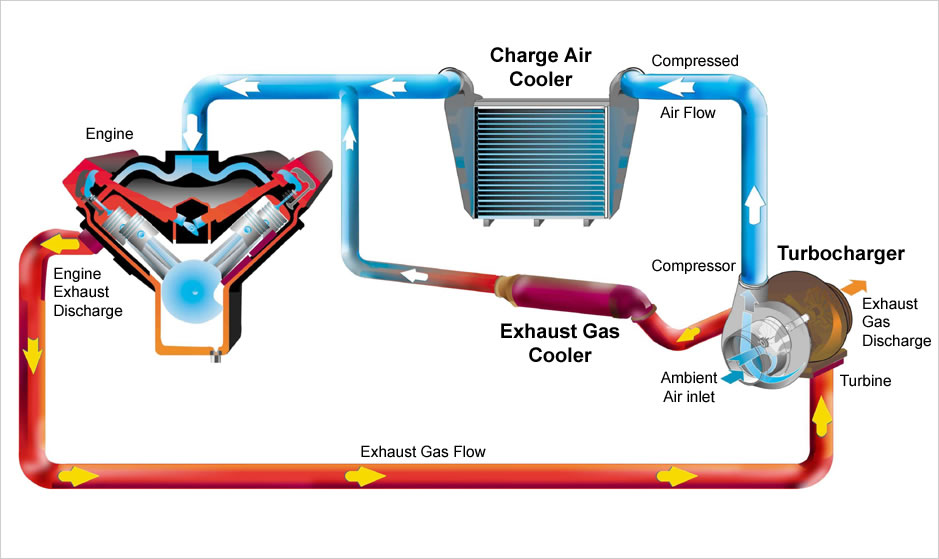

Un turbocompresor es un dispositivo que se utiliza para aumentar la potencia del motor o se puede decir la eficiencia de un motor al aumentar la cantidad de aire que ingresa a la cámara de combustión. Más aire en la cámara de combustión significa que se admitirá más cantidad de combustible en el cilindro y, como resultado, se obtendrá más potencia del mismo motor si el turbocompresor está instalado en él.

En pocas palabras, un turbocompresor es una especie de bomba de aire que toma aire a presión ambiental (presión atmosférica), lo comprime a una presión más alta y pasa el aire comprimido al motor a través de las válvulas de admisión.

Actualmente, los turbos se utilizan principalmente en motores diésel, pero actualmente se está avanzando hacia la turbocompresión en los motores de gasolina de serie.

La cantidad de motor que realmente entra en el cilindro del motor, en comparación con la cantidad teórica si el motor pudiera mantener la presión atmosférica, se llama eficiencia volumétrica y el objetivo del turbocompresor es mejorar la eficiencia volumétrica de un motor aumentando la densidad del gas de admisión. .

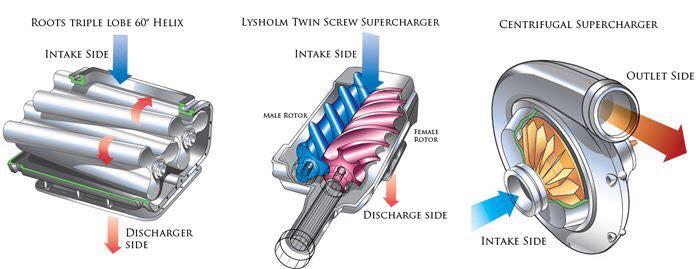

El turbocompresor extrae el aire de la atmósfera y lo comprime con la ayuda de un compresor centrífugo antes de que entre en el colector de admisión a mayor presión. Esto da como resultado una mayor cantidad de aire que ingresa a los cilindros en cada carrera de admisión. El compresor centrífugo obtiene energía de la energía cinética de los gases de escape del motor.

COMPONENTES DEL TURBOCARGADOR

El turbocompresor tiene tres componentes principales.

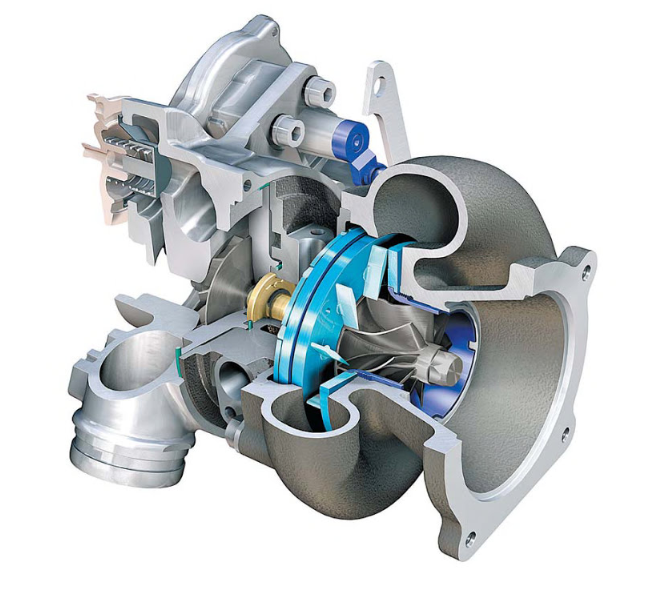

- 1. La turbina, que es casi una turbina de entrada radial.

- 2. El compresor es casi un compresor centrífugo.

- 3. El conjunto giratorio del cubo central.

Un turbocompresor se compone de dos secciones principales: la turbina y el compresor. La turbina consta de una rueda de turbina y una carcasa de turbina. La función de la carcasa de la turbina es guiar los gases de escape hacia la rueda de la turbina.

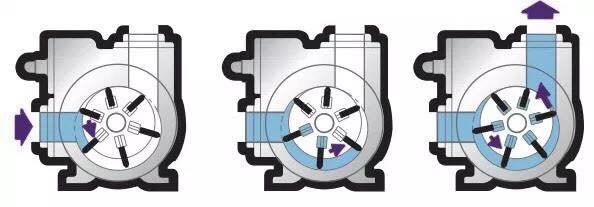

La energía de los gases de escape hace girar la rueda de la turbina y luego el gas sale de la carcasa de la turbina a través de un área de salida de escape. El compresor también consta de dos partes: la rueda del compresor y la carcasa del compresor.

El modo de acción del compresor es opuesto al de la turbina. La rueda del compresor está unida a la turbina mediante un eje de acero forjado y, a medida que la turbina hace girar la rueda del compresor, el giro a alta velocidad aspira aire y lo comprime.

Luego, la carcasa del compresor convierte la corriente de aire de alta velocidad y baja presión en una corriente de aire de alta presión y baja velocidad mediante un proceso llamado difusión. El aire comprimido ingresa al motor, lo que le permite quemar más combustible para producir más potencia.

PRINCIPIO DE FUNCIONAMIENTO

Un turbocompresor consta principalmente de dos secciones principales: la turbina y el compresor. La turbina consta de una rueda de turbina y una carcasa de turbina, cuya función es conducir los gases de escape hacia la rueda de turbina. La energía cinética de los gases de escape se convierte en mecánica después de golpear los álabes de la turbina. La salida de escape ayuda a que los gases de escape salgan de la turbina. La rueda del compresor en el turbocompresor está unida a una turbina con la ayuda de un eje de acero y, a medida que la turbina hace girar la rueda del compresor, aspira la corriente de aire de alta velocidad y baja presión y la convierte en aire de alta presión y baja velocidad. arroyo. Este aire comprimido ingresa al motor con mayor cantidad de combustible y, por lo tanto, produce más potencia.

Los gases de escape residuales del motor se utilizan para accionar una rueda de turbina, que está conectada a una rueda de compresor mediante un eje. El compresor o rueda de aire aspira aire a través de los filtros de aire y lo pasa al motor.

A medida que los gases residuales son expulsados del motor, se dirigen a la turbina o rueda caliente del turbo y así completa el ciclo.

- Captura

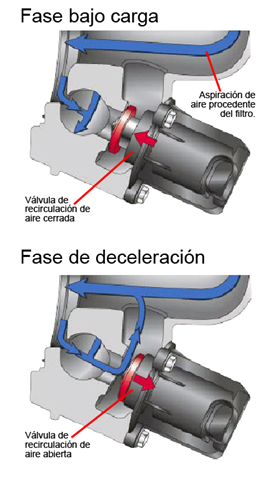

En lugar de escapar por el tubo de escape, los gases calientes producidos durante la combustión fluyen hacia el turbocompresor. Los cilindros dentro de un motor de combustión interna se disparan en secuencia (no todos a la vez), por lo que los gases de escape salen de la cámara de combustión en pulsos irregulares.

Los turbocompresores convencionales de entrada única dirigen esos pulsos irregulares de escape hacia la turbina de una manera que los hace chocar e interferir entre sí, reduciendo la fuerza del flujo. Por el contrario, un turbocompresor de doble entrada recoge los gases de escape de pares de cilindros en una secuencia alterna.

- Girar

El escape golpea las palas de la turbina, haciéndolas girar hasta 150.000 rpm. Los pulsos alternos del escape ayudan a eliminar el retraso del turbo.

- Ventilación

Una vez cumplido su propósito, los gases de escape fluyen a través de una salida hacia el convertidor catalítico, donde se eliminan el monóxido de carbono, los óxidos nitrosos y otros contaminantes antes de salir por el tubo de escape.

- Comprimir

Mientras tanto, la turbina alimenta un compresor de aire, que recoge aire frío y limpio de un respiradero y lo comprime hasta un 30 por ciento por encima de la presión atmosférica, o casi 19 libras por pulgada cuadrada. El aire denso y rico en oxígeno fluye hacia la cámara de combustión.

El oxígeno adicional hace posible que el motor queme gasolina de manera más completa, generando más rendimiento con un motor más pequeño. Como resultado, el motor Twin Power genera un 30 por ciento más de potencia que uno sin turbo del mismo tamaño.

Sigue el siguiente proceso

- La entrada de aire del motor aspira aire frío y lo envía al compresor.

- El compresor comprime el aire entrante y lo calienta. Luego expulsa el aire caliente.

- El aire caliente se enfría al pasar por el intercambiador de calor y entra en la entrada de aire del cilindro.

- El aire frío arde dentro de la cámara de combustión a un ritmo más rápido debido a que transporta más oxígeno.

- Debido a que se quema más combustible, la producción de energía será mayor y más rápida y el motor podrá enviar más potencia a las ruedas.

- Los gases residuales calientes saldrán de la cámara y pasarán por la turbina en la salida de escape.

- La turbina gira a alta velocidad y también hace girar el compresor, ya que ambos están montados en el mismo eje.

- Los gases de escape salen del coche por el tubo de escape. Gastan menos energía que un motor sin turbocompresor.

TIPOS DE TURBOCOMPRESOR

- Turbo único

Los turbocompresores individuales por sí solos tienen una variabilidad ilimitada. Diferenciar el tamaño de la rueda del compresor y la turbina dará lugar a características de par completamente diferentes. Los turbos grandes generarán una alta potencia en la gama alta, pero los turbos más pequeños proporcionarán un mejor gruñido en las bajas ya que giran más rápido. También hay turbos simples con cojinetes de bolas y cojinetes lisos. Los rodamientos de bolas proporcionan menos fricción para que giren el compresor y la turbina, por lo que son más rápidos de enrollar (al tiempo que aumentan los costos).

Ventajas

- Una forma rentable de aumentar la potencia y la eficiencia de un motor.

- Simple, generalmente la más fácil de instalar de las opciones de turbocompresor.

- Permite utilizar motores más pequeños para producir la misma potencia que los motores de aspiración natural más grandes, lo que a menudo puede eliminar peso.

Desventajas

- Los turbos simples tienden a tener un rango de RPM efectivas bastante estrecho. Esto hace que el tamaño sea un problema, ya que tendrás que elegir entre un buen par a bajas revoluciones o una mejor potencia a altas revoluciones.

- La respuesta del turbo puede no ser tan rápida como las configuraciones turbo alternativas.

- Twin Turbo

Al igual que con los turbocompresores simples, existen muchas opciones cuando se utilizan dos turbocompresores. Podría tener un solo turbocompresor para cada bancada de cilindros (V6, V8, etc.). Alternativamente, se podría usar un solo turbocompresor para bajas RPM y pasar a un turbocompresor más grande para altas RPM (I4, I6, etc.). Incluso podría tener dos turbos de tamaño similar, donde uno se usa a bajas RPM y ambos a altas RPM. En los BMW X5 M y X6 M se utilizan turbos Twin-Scroll, uno a cada lado del V8.

Ventajas

- Para los turbos gemelos paralelos en motores en forma de “V”, los beneficios (y los inconvenientes) son muy similares a las configuraciones de un solo turbo.

- Para turbos secuenciales o usando un turbo a bajas RPM y ambos a altas RPM, esto permite una curva de torsión mucho más amplia y plana. Mejor par a bajas revoluciones, pero la potencia no disminuirá a altas RPM como con un pequeño turbo único.

Desventajas

- Costo y complejidad, ya que casi se han duplicado los componentes del turbo.

- Existen formas más ligeras y eficientes de lograr resultados similares (como se analiza más adelante).

- Turbo de doble desplazamiento

Un turbo funciona con gases de escape que se redirigen para hacer girar las palas de la turbina y forzar el ingreso de aire al motor. Ahora, los cilindros de un motor se disparan en secuencia, lo que significa que los gases de escape ingresan al turbo en pulsos. Como probablemente puedas imaginar, estos pulsos pueden superponerse e interferir fácilmente entre sí al alimentar el turbo, y un turbocompresor de doble entrada resuelve este problema mediante el uso de una carcasa de turbina de entrada dividida y un colector de escape específico que empareja los cilindros correctos con cada uno. Desplazarse. En un vehículo de cuatro cilindros, puede tener el primer y cuarto cilindros alimentando un scroll, y dos y tres alimentando otro. Esto significa que hay menos superposición de pulsos y menos retraso.

Ventajas

- Se envía más energía a la turbina de escape, lo que significa más potencia.

- Es posible obtener un rango más amplio de RPM de impulso efectivo en función de los diferentes diseños de desplazamiento.

- Es posible lograr una mayor superposición de válvulas sin obstaculizar la evacuación del escape, lo que significa más flexibilidad de ajuste.

Desventajas

- Requiere una disposición del motor y un diseño de escape específicos (por ejemplo: I4 y V8, donde se pueden alimentar 2 cilindros a cada espiral del turbo, a intervalos iguales).

- Costo y complejidad frente a los turbos simples tradicionales.

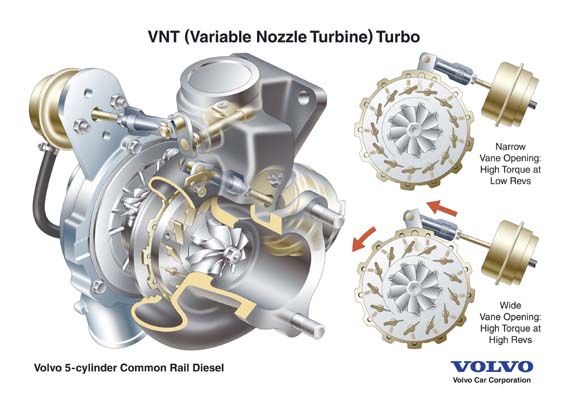

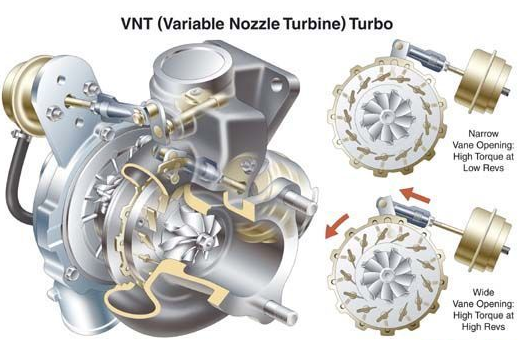

- Turbocompresor de geometría variable (VGT)

Un turbo de geometría variable (VGT) es una solución de energía costosa y compleja que prevalece especialmente en los motores diésel. Un VGT tiene un anillo de paletas de forma aerodinámica en la carcasa de la turbina que puede alterar su relación área-radio para que coincida con las revoluciones del motor. A bajas revoluciones, la relación área-radio crea más presión y velocidad para acelerar el turbo de manera más efectiva. A mayores revoluciones, la relación aumenta para dejar entrar más aire. El resultado es un rango de impulso más amplio y menos retraso.

Ventajas

- Curva de torsión amplia y plana. Turbocompresor eficaz en un rango de revoluciones muy amplio.

- Requiere solo un turbo, lo que simplifica una configuración de turbo secuencial en algo más compacto.

Desventajas

- Normalmente sólo se utiliza en aplicaciones diésel donde los gases de escape son más bajos para que las paletas no se dañen con el calor.

- Para las aplicaciones de gasolina, el costo normalmente las mantiene fuera, ya que se deben utilizar metales exóticos para mantener la confiabilidad. La tecnología se ha utilizado en el Porsche 997, aunque existen muy pocos motores de gasolina VGT debido al costo asociado.

- Turbocompresor variable de doble entrada

Un turbo variable de doble desplazamiento combina un VGT con una configuración de doble desplazamiento, por lo que a bajas revoluciones, uno de los desplazamientos se cierra por completo, forzando todo el aire hacia el otro. Esto da como resultado una buena respuesta del turbo y potencia a bajas revoluciones. A medida que acelera, se abre una válvula para permitir que entre aire en la otra espiral (este es un proceso completamente variable, lo que significa que la válvula se abre en pequeños incrementos), se obtiene un buen rendimiento de alta gama. Obtienes el tipo de rendimiento con un solo turbo que normalmente solo podrías obtener con una configuración de doble turbo.

Ventajas

- Significativamente más baratos (en teoría) que los VGT, lo que constituye un argumento aceptable para el turbocompresor de gasolina.

- Permite una curva de torsión amplia y plana.

- Diseño más robusto que un VGT, dependiendo de la selección del material.

Desventajas

- Costo y complejidad frente al uso de un solo turbo o el tradicional doble desplazamiento.

- Se ha jugado con esta tecnología antes (por ejemplo: válvula de carrete rápido) pero no parece tener éxito en el mundo de la producción. Es probable que existan desafíos adicionales con la tecnología.

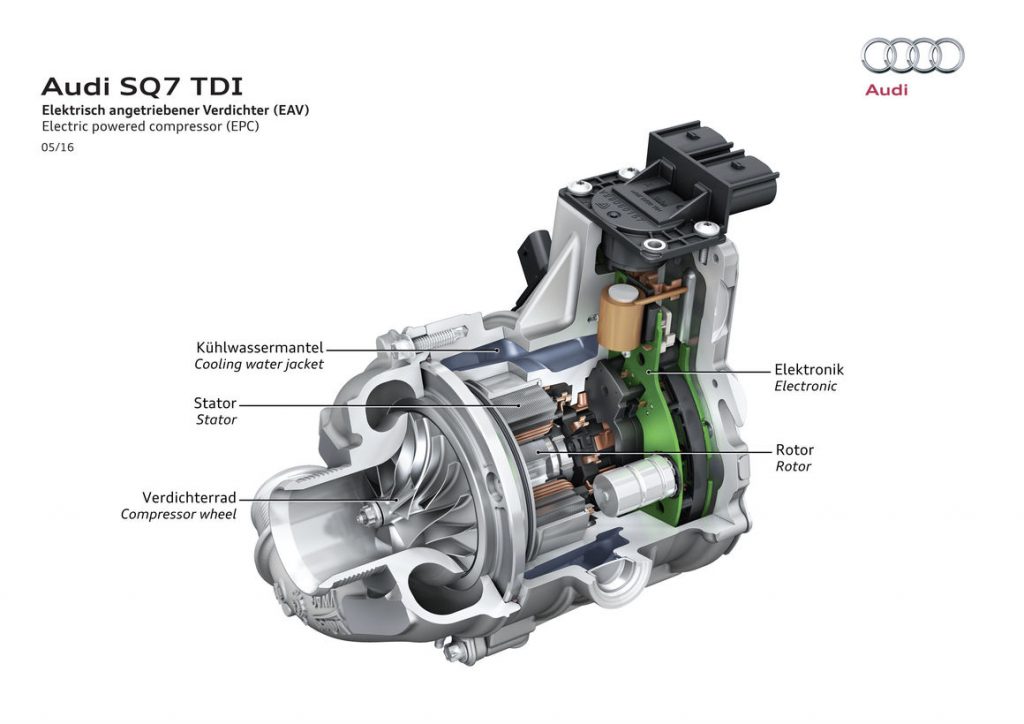

- Turbocompresores eléctricos

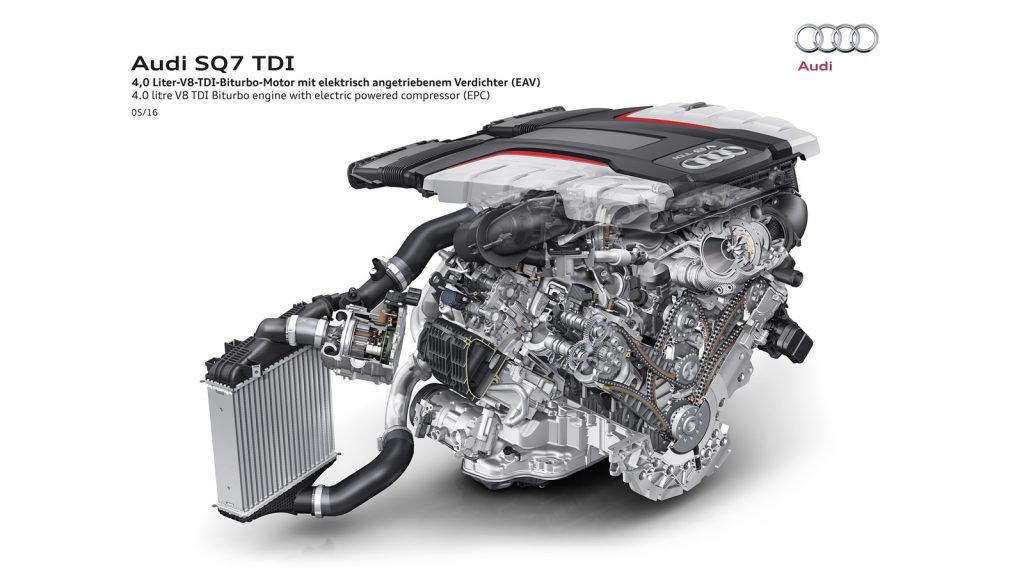

Un avance muy reciente es la introducción de turbos con compresores eléctricos. Un ejemplo es el propulsor de BorgWarner, que es un compresor accionado eléctricamente. El compresor proporciona un impulso instantáneo al motor hasta que el turbocompresor se ha acelerado lo suficiente. Se puede encontrar una versión similar de esto en el SQ7 de Audi. Con el impulso instantáneo, el retraso se convierte en cosa del pasado, pero nuevamente, el sistema es costoso y complejo. Un compresor necesita un motor, que a su vez necesita ser alimentado, por lo que este no es un sistema sencillo de implementar.

Ventajas

- Al conectar directamente un motor eléctrico a la rueda del compresor, el retraso del turbo y la cantidad insuficiente de gases de escape se pueden eliminar virtualmente haciendo girar el compresor con energía eléctrica cuando sea necesario.

- Conectando un motor eléctrico a la turbina de escape se puede recuperar la energía desperdiciada (como se hace en la Fórmula 1).

- Un rango de RPM efectivo muy amplio con par uniforme en todo momento.

Desventajas

- Costo y complejidad, ya que ahora debe tener en cuenta el motor eléctrico y asegurarse de que permanezca frío para evitar problemas de confiabilidad. Esto también se aplica a los controladores agregados.

- El embalaje y el peso se convierten en un problema, especialmente con la adición de una batería a bordo, que será necesaria para suministrar suficiente energía al turbo cuando sea necesario.

- Los VGT o twin-scrolls pueden ofrecer beneficios muy similares (aunque no al mismo nivel) por un costo significativamente menor.